C&C Training has come up with an insightful practical class-room experience to train people in non-licensed Asbestos Works.

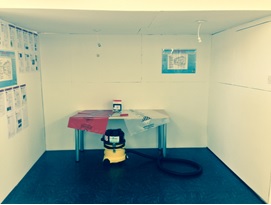

Being UKATA approved, C&C Training has built a Category B training facility in one of its training rooms in Leighton Buzzard.

The new provision, which has been designed to replicate a typical room scenario, will be used to conduct practical Category B1, B2 & B3 training and assessments to the highest standards.

Using dummy asbestos-containing materials (ACMs), C&C is able to provide a diverse selection of practical elements from the HSG210 Asbestos Essentials publication which forms the basis of Category B Non-Licensed Asbestos Works including notifiable non-licensed work (NNLW).

The facility has been built at just the right time as this week the Health and Safety Executive launched a new safety campaign after identifying 20 tradespeople a week die from asbestos-related diseases.

In a recent survey, the HSE found that construction workers, carpenters, painters and decorators could come into contact with deadly asbestos more than 100 times a year.

Only a third of those asked were able to identify all the correct measures for safe asbestos working, while more than half made at least one potentially lethal mistake in staying safe.

Alarmingly, the survey revealed that many believed in common myths surrounding safe working such as drinking a glass of water or opening a window will protect them from deadly dust.

The research, conducted by Censuswide, also concluded that more than half knew asbestos could be found in buildings built before 1970, but only 15 per cent new that it may be present in buildings built up to the year 2000.

The HSE has now launched the new safety campaign by distributing asbestos safety kits and also a new web app available for download from the HSE Website.

Meanwhile, C&C Training can cater for all your training needs. Its new realistic centre can provide training and assessments in the following categories:

A1 – Drilling holes in asbestos insulating board (AIB)

A4 – Removing a single AIB (less than 1m2) fixed in with nails/screws

A5 – Cleaning light fittings attached to AIB

A6 – Repairing minor damage to AIB

A7 – Painting undamaged AIB

A8 – Enclosing undamaged asbestos materials to prevent impact damage

A9 – Drilling holes in Asbestos Cement (AC) and other highly bonded materials

A11 – Removing AC debris

A20 – Laying cables in areas containing undamaged ACMs

A23 – Removing asbestos containing floor tiles and mastic

A27 – Inserting and removing screws through textured coatings

A28 – Removing textured coating from a small area e.g. 1m2

A29 – Cleaning up debris following the collapse of a ceiling or wall covered in a textured coating

A33 – Replacing an Asbestos containing fuse box or single fuse assembly

A34 – Removing pins and nails from an AIB Panel

A36 – Removing an AC panel outside, beside or beneath a window

A37 – Removing asbestos containing mastic, sealant, filler, beading, putty or fixing

C&C Training has not stopped there, as the company plans to support the fixed training facility with standalone training modules to cater for the following:

A10 – Cleaning debris from guttering on an AC roof

A13 – Repairing damaged AC

A14 – Removing AC sheets, gutters etc. and dismantling a small AC structure

A16 – Painting AC sheets

C&C’s Head of Health and Safety Services, Matthew St John said: “The facility will allow our instructors to deliver training in a safe and controlled environment that reflects the workplace in which the actual activities take place, adding realism and appreciation to the training. The facility will also allow the instructors to set realistic tasks for those delegates returning for their annual refreshers. A series of scenarios will be developed from activities identified in the delegate training needs analysis and a potentially ‘live’ working environment will be constructed.”